Multiple Compressors System Control (MCSC)

MCSC is an innovative product developed by BaHN Automation for multiple compressor control based on a patented concept of Fouress Company LLC, USA

More than 30 systems have been supplied & successfully installed for vide spectrum of industries in India, USA & Mexico through M/s Optimum Air Solutions Pvt. Ltd., Bangalore.

Use of MCSC has benefited the customers to save energy to the extent of 15 to 30%.

Customers have also derived indirect benefits viz., reduced manpower and maintenance costs apart from better utilization of compressors in using MCSC.

About Compressor Air

- Apart from electricity & water, compressed air is a very important utility in any manufacturing, process industry

- About 7% of energy consumed all over the world is on account of compressed air generation.

- Operational cost / annum of a compressor is about five times the cost of the compressor itself.

- Every 1psi more pressure requires 1% more capacity.

- Every 2psi more pressure consumes 1% more electricity

- Reducing operating pressure by 10psi will reduce energy consumption by 5% if the system is 100% regulated and up to 15% if the system is 100% unregulated

- Many compressed air systems waste 40% energy due to

- Inefficient operation

- Artificial demand

- Idle running

MCSC – Overview & Principle

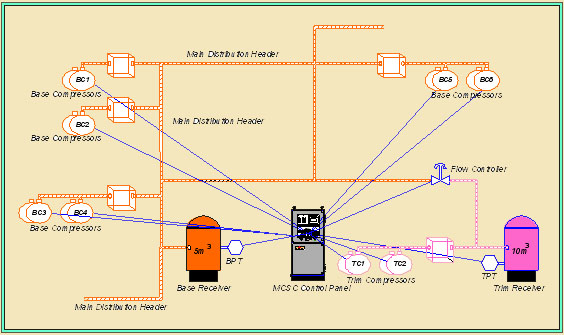

- Based on air consumption, energy audit, the compressors are grouped as base and trim compressors

- Base compressors meets the base or main load of the plant

- Trim compressors along with trim receiver caters to plant load fluctuations

- Trim compressors always maintain air in trim receiver at slightly higher header pressure

- The Flow Control Valve regulates and maintain constant header pressure for varying flow conditions

- The main header pressure can be set as required by a PID

- MCSC monitors the dynamics of the systems by monitoring main header pressure, trim receiver pressure

- Depending on the plant load, MCSC operates required number of base / trim compressors to maintain set header pressure

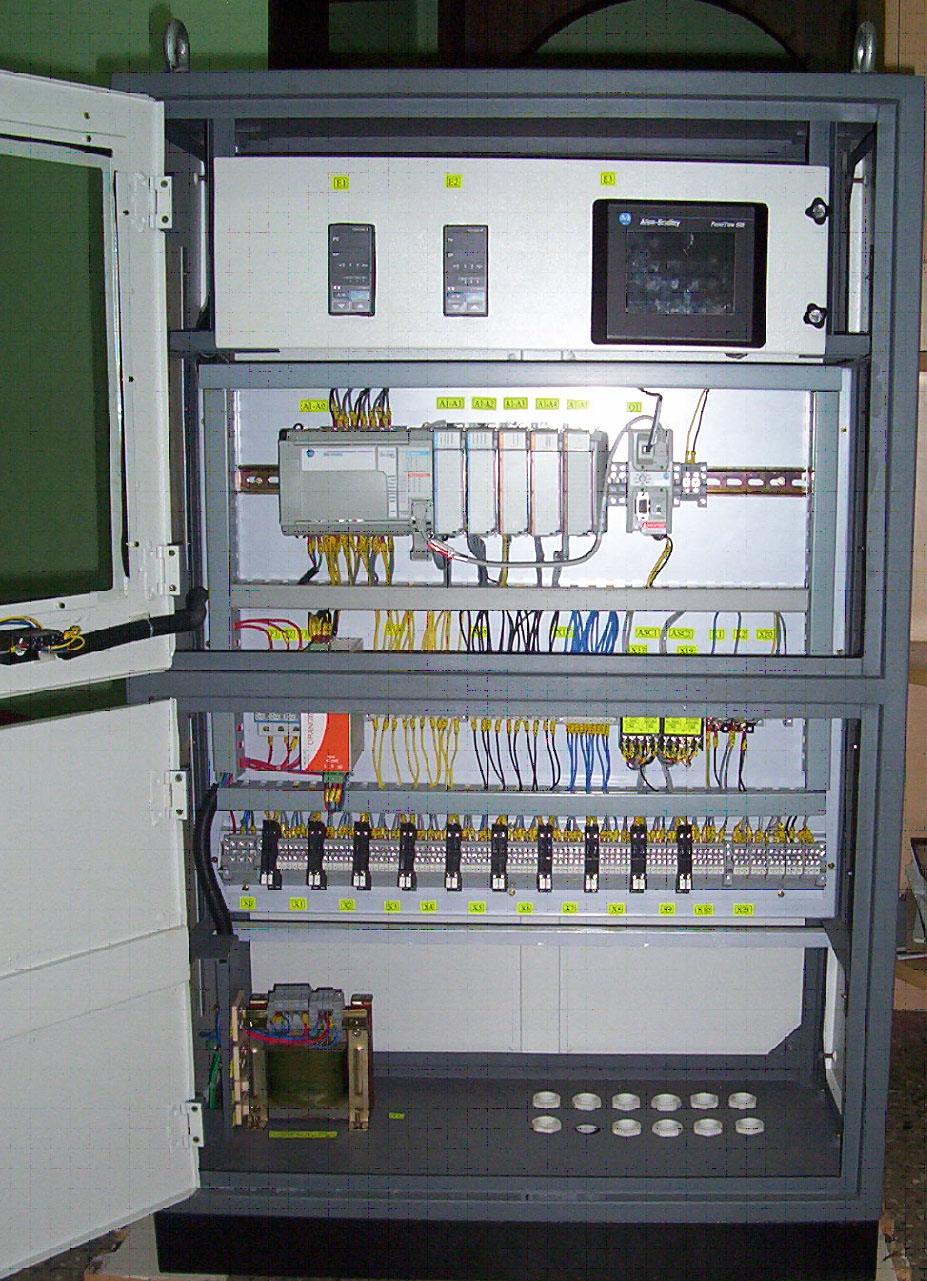

MCSC – Hardware & System Features

- Hardware based on reputed Allen Bradley make PLC

- SLC as well as MicroLogix PLC platforms

- Either monochrome or color touch panels as GUI

- Yokogawa make PID controller for setting of header pressure and control of Flow Control Valve

- Hardware & software customization for 4, 6, 8, 10 and 12 compressors

- Industrial grade sub-systems, items, components

- Modular construction and accessibility for all items

- Screw on terminations for easy field wiring

- Installation & commissioning without any plant shutdown

- MCSC can interface with screw as well as reciprocating compressors of any make and type

MCSC – GUI Features

- All system parameters can be monitored on Touch Panel ( GUI )

- Display of operational status of each compressor

- Compressors parameters viz., loading / unloading pressure, load, stop, rest delays and so on can set or altered as required

- Logging, display of faults with date & time stamp

- Hierarchical level based password protection